NEMA released NEMA ANSI c136.31-2018 "vibration testing of road and area lighting products in North America" on June 5, 2018. The following is the detailed explanation:

1. Test range:

NEMA ANSI c136.31-2018 provides a method for evaluating the vibration test of road and area lighting products and for evaluating the minimum vibration resistance of road and area lighting.

2. Road and area lighting will be affected by external vibration includes the following aspects in the actual use:

A. vibration caused by wind.

B. vibration caused by traffic.

3. Test method:

3.1 Inductor mounting

A sensor should be installed at the center of the sample (if there is no enough room, it shall be installed at the extension line in the center) to measure the amplitude (or acceleration) of the sample response under test.

3.2 Sample installation

The sample shall be mounted on the fixture, which shall be mounted on the vibration equipment. It is necessary to make special fixture in practical use.

3.3 test procedures

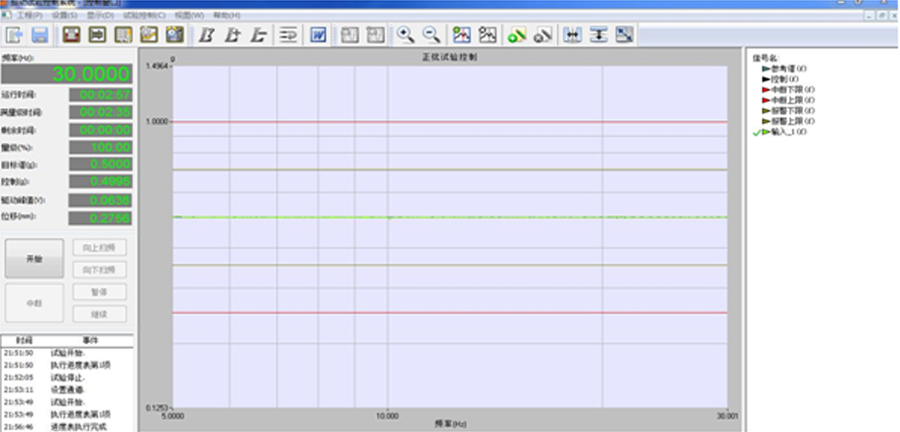

The vibration test was performed at frequencies of 2~30Hz, with a low acceleration and a resonance search at a sweep speed of 1oct/min. The resonance frequencies within this range were found (if the response spectrum and the control spectrum were approximately equal, the highest 30Hz would be used as the resonance frequency of the test). At the frequency that we just figured out, it vibrates 100,000 times, and the time of oscillation is 100,000/60f, and f is the resonance frequency. The above steps shall be carried out in the three mutually perpendicular directions of the product. The vibration acceleration shall be in accordance with the application of the product, as shown in table 1 and table 2 in the standard. The normal application is 1.5g and the Bridge/overpass application is 3.3g which are commonly used.

4. Matters needing attention:

4.1 The vibration test time is unknown before the test. The maximum vibration time is about 3 hours, including the vibration search time. The total test time is about 4 hours. Since the early stage of the test involves product installation and equipment disassembly, the test time is expected to last 1 to 2 days.

4.2 The products are usually large and heavy. The fixture shall be made as light as possible and the connection shall be rigid, because the flexible connection has a great impact on the transmission of vibration.

4.3 fixtures have influence on test results. Special fixtures should be provided for testing.

5. Other series of standards

NEMA ANSI C136.10 road and area lighting - locked-in optical controls and supporting sockets - physical and electrical interchangeability and testing

NEMA ANSI C136.18 road and area lighting equipment - High bar side mounted lamps

NEMA ANSI C136.24 road and area lighting - Non-locking (button) type light sensor

NEMA ANSI C136.26 - road and area lighting - Guide for troubleshooting of high pressure sodium lamps

NEMA ANSI C136.28 road and area lighting - Glass lenses for lamps

NEMA ANSI C136.35 electrical AIDS for road and area lighting fixtures (lead)

NEMA ANSI C136.41 road and area lighting equipment - Dimming control between external lock finalizing light control and ballast/starter

BACL reliability service type:

1. Product reliability technical evaluation

2. Product reliability test

3. Product failure analysis

4. Product life test

5. Product durability test

With over 20 years’ rich experience in professional lighting industry and a strong technical team on test, analysis and solution, BACL can offer comprehensive, professional, in-depth testing services and solutions in product reliability growth, identification, acceptance, durability service life analysis, optical performance parameter evaluation, research and development validation, prenatal evaluation, quality control, etc,. BACL can provide you with one-stop services for lighting product on safety, electromagnetic compatibility, energy efficiency, physics and chemistry and reliability!

BACL Service:

As the NRTL recognized by North America OSHA and the safety certification body recognized by Canada SCC, BACL is also authorized and recognized by A2LA, IAS, IECEE, CNAS, CMA, FDA, ACMA, SAA and ISTA, etc. At present, it has reliability testing laboratories in Shenzhen, Dongguan, Kunshan, Xiamen, Taiwan, etc, and can provide our customers with the climate reliability test, the mechanical reliability test, comprehensive environment test, and the solution of the reliability growth, identification, acceptance and life analysis for lighting products, power products, electric tools, communication products, metal materials and components, coatings, tape products, various types of carton packaging. Welcome to consult us!

CN/中国

CN/中国  US/USA

US/USA  KR/Korea

KR/Korea  DE/Germany

DE/Germany  ES/Spain

ES/Spain VN/Việtnam

VN/Việtnam