As defined in the Code of Federal Regulations (CFR), “Metal halide lamp fixture" means a light fixture for general lighting application designed to be operated with a metal halide lamp and a ballast for a metal halide lamp. 10 CFR 431.322. Manufacturers have been required to comply with the U.S. Department of Energy (DOE) energy conservation standards for metal halide lamp fixtures since 2007.

On October 3, 2023,DOE has published a notification of proposed determination and request for comment on amended energy conservation standards for metal halide lamp fixtures (MHLFs):

l DOE will accept comments, data, and information on or before December 4, 2023;

l DOE will hold a public webinar upon request. Please request a public webinar no later than October 17, 2023;

l Interested persons may submit comments identified by docket number EERE–2022–BT– STD–0023, by email (MHLF2022STD0023@ee.doe.gov), Federal eRulemaking portal (http://www.regulations.gov). Follow the instructions for submitting comments.

URL:

https://www.regulations.gov/document/EERE-2022-BT-STD-0023-0004

Current Standard:

Metal halide lamp fixtures manufactured and distributed in commerce, as defined by 42 U.S.C. 6291(16), must meet the energy conservation standards specified in the Code of Federal Regulations at 10 CFR 431.326.

Current Test Procedure:

To determine that metal halide lamp fixtures that are currently manufactured or distributed into commerce are in compliance with DOE standards, manufacturers must follow the test procedure methods specified at 10 CFR 431.324.

Current MHLFS standard requirements:

(a) Except as provided in paragraph (b) of this section, each metal halide lamp fixture manufactured on or after January 1, 2009, and designed to be operated with lamps rated greater than or equal to 150 watts but less than or equal to 500 watts shall contain:

(1) A pulse-start metal halide ballast with a minimum ballast efficiency of 88 percent;

(2) A magnetic probe-start ballast with a minimum ballast efficiency of 94 percent; or

(3) A nonpulse-start electronic ballast with either a minimum ballast efficiency of 92 percent for wattages greater than 250 watts; or a minimum ballast efficiency of 90 percent for wattages less than or equal to 250 watts.

(b) The standards described in paragraph (a) of this section do not apply to:

(1) Metal halide lamp fixtures with regulated lag ballasts;

(2) Metal halide lamp fixtures that use electronic ballasts that operate at 480 volts; or

(3) Metal halide lamp fixtures that;

(i) Are rated only for 150 watt lamps;

(ii) Are rated for use in wet locations; as specified by the National Fire Protection Association in NFPA 70; and

(iii) Contain a ballast that is rated to operate at ambient air temperatures above 50 °C, as specified in UL 1029.

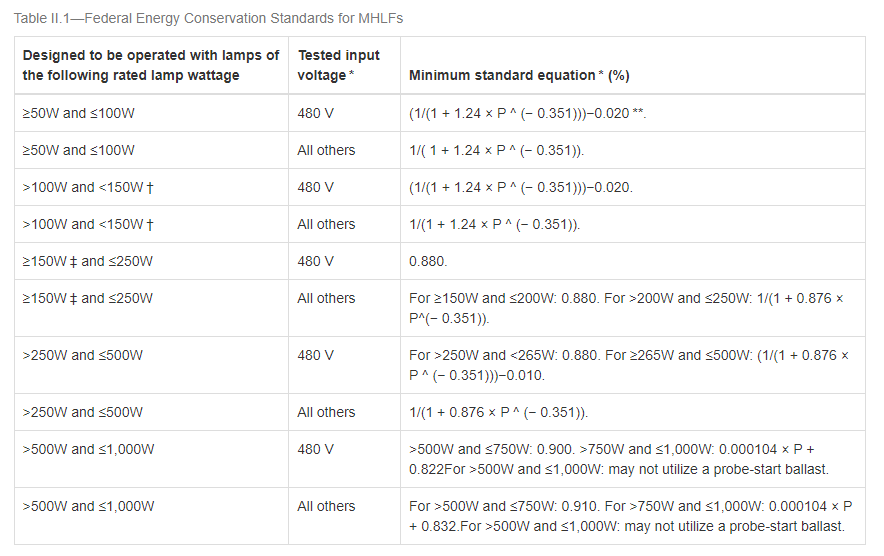

(c) Except when the requirements of paragraph (a) of this section are more stringent (i.e., require a larger minimum efficiency value) or as provided by paragraph (e) of this section, each metal halide lamp fixture manufactured on or after February 10, 2017, must contain a metal halide ballast with an efficiency not less than the value determined from the appropriate equation in the following table:

† Includes 150 W fixtures specified in paragraph (b)(3) of this section, that are fixtures rated only for 150 W lamps; rated for use in wet locations, as specified by the NFPA 70, section 410.4(A); and containing a ballast that is rated to operate at ambient air temperatures above 50 °C, as specified by UL 1029.

‡ Excludes 150 W fixtures specified in paragraph (b)(3) of this section, that are fixtures rated only for 150 W lamps; rated for use in wet locations, as specified by the NFPA 70, section 410.4(A); and containing a ballast that is rated to operate at ambient air temperatures above 50 °C, as specified by UL 1029.

†† P is defined as the rated wattage of the lamp the fixture is designed to operate.

‡‡ Tested input voltage is specified in 10 CFR 431.324.

(d) Except as provided in paragraph (e) of this section, metal halide lamp fixtures manufactured on or after February 10, 2017, that operate lamps with rated wattage >500 W to ≤1000 W must not contain a probe-start metal halide ballast.

(e) The standards described in paragraphs (c) and (d) of this section do not apply to:

(1) Metal halide lamp fixtures with regulated-lag ballasts;

(2) Metal halide lamp fixtures that use electronic ballasts that operate at 480 volts; and

(3) Metal halide lamp fixtures that use high-frequency electronic ballasts.

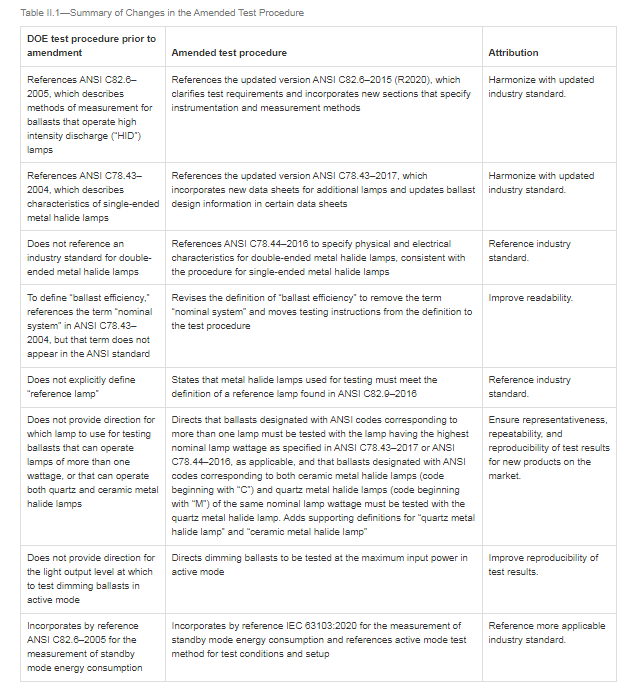

DOE has published a Federal Register notice Final Rule adopting amendments to its test procedure for metal halide lamp fixtures (MHLFs) to incorporate by reference new relevant industry standards as well as update to latest versions of existing references:

l clarify the selection of reference lamps used for testing;

l specify the light output level at which to test dimming ballasts;

l revise definitions and reorganize the content of the test procedure for better readability and clarity;

l revise the standby mode test method for MHLFs.

Detailed list of revised and updated regulations

Section 431.322 is amended by:

a. Removing the definition for “AC control signal”;

b. Revising the definition for “Ballast efficiency”;

c. Adding in alphabetical order a definition for “Ceramic metal halide lamp”;

d. Removing the definition for “DC control signal”;

e. Adding in alphabetical order definitions for “Quartz metal halide lamp” and “Reference lamp”; and

f. Removing the definition for “Wireless control signal”.

431.322 Definitions concerning metal halide lamp ballasts and fixtures.

Ballast efficiency means, in the case of a high intensity discharge fixture, the efficiency of a lamp and ballast combination, expressed as a percentage, and calculated in accordance with the following formula:

Efficiency = P out /P in where:

(1) P out equals the measured operating lamp wattage; and

(2) P in equals the measured operating input wattage.

(3) The lamp, and the capacitor when the capacitor is provided, shall constitute a nominal system in accordance with the ANSI C78.43–2017;

(4) For ballasts with a frequency of 60 Hz, Pin and Pout shall be measured after lamps have been stabilized according to Section 4.4 of ANSI C82.6–2015 using a wattmeter with accuracy specified in Section 4.5 of ANSI C82.6–2015; and

(5) For ballasts with a frequency greater than 60 Hz, Pin and Pout shall have a basic accuracy of ±0.5 percent at the higher of either 3 times the output operating frequency of the ballast or 2.4 kHz.

Ceramic metal halide lamp means a metal halide lamp with an arc tube made of ceramic materials.

Quartz metal halide lamp means a metal halide lamp with an arc tube made of quartz materials.

Reference lamp is a metal halide lamp that meets the operating conditions of a reference lamp as defined by ANSI C82.9–2016.

Section 431.324 is revised to read as follows:

431.324 Uniform test method for the measurement of energy efficiency and standby mode energy consumption of metal halide lamp ballasts.

(a) Scope. This section provides test procedures for measuring, pursuant to EPCA, the energy efficiency of metal halide lamp ballasts.

After July 25, 2022, and prior to December 21, 2022, any representations with respect to energy use or efficiency of metal halide lamp fixtures must be in accordance with the results of testing pursuant to this section or the test procedures as they appeared in 10 CFR 431.324 as it appeared in the 10 CFR parts 200–499 edition revised as of January 1, 2022. On or after December 21, 2022, any representations, including certifications of compliance for metal halide lamp fixtures subject to any energy conservation standard, made with respect to the energy use or efficiency of metal halide lamp fixtures must be made in accordance with the results of testing pursuant to this section.

(b) Active mode procedure

(1) General instructions.

Specifications in referenced standards that are recommended, that “shall” or “should” be met, or that are not otherwise explicitly optional, are mandatory. In cases where there is a conflict between any industry standard(s) and this section, the language of the test procedure in this section takes precedence over the industry standard(s).

(2) Test conditions and setup.

(i) The power supply, ballast conditions, lamp position, and instrumentation must all conform to the requirements specified in Section 4.0 of ANSI C82.6–2015 (R2020) .

(ii) Airflow in the room for the testing period must be ≤0.5 meters/second.

(iii) Test circuits must be in accordance with the circuit connections specified in Section 6.3 of ANSI C82.6–2015 (R2020).

(iv) For ballasts designed to operate lamps rated less than 150 W that have 120 V as an available input voltage, testing must be performed at 120 V. For ballasts designed to operate lamps rated less than 150 W that do not have 120 V as an available voltage, testing must be performed at the highest available input voltage. For ballasts designed to operate lamps rated greater than or equal to 150 W that have 277 V as an available input voltage, testing must be conducted at 277 V. For ballasts designed to operate lamps rated greater than or equal to 150 W that do not have 277 V as an available input voltage, testing must be conducted at the highest available input voltage.

(v) Operate dimming ballasts at maximum input power.

(vi) Select the metal halide lamp for testing as follows:

(A) The metal halide lamp used for testing must meet the specifications of a reference lamp as defined by ANSI C82.9–2016 and the rated values of the corresponding lamp data sheet as specified in ANSI C78.43–2017 for single-ended lamps and ANSI C78.44–2016 for double-ended lamps.

(B) Ballasts designated with ANSI codes corresponding to more than one lamp must be tested with the lamp having the highest nominal lamp wattage as specified in ANSI C78.43–2017 or ANSI C78.44–2016, as applicable.

(C) Ballasts designated with ANSI codes corresponding to both ceramic metal halide lamps (code beginning with “C”) and quartz metal halide lamps (code beginning with “M”) of the same nominal lamp wattage must be tested with the quartz metal halide lamp.

(3) Test method

(i) Stabilization criteria

(A) General instruction. Lamp must be seasoned as prescribed in Section 4.4.1 of ANSI C82.6–2015 (R2020).

(B) Basic stabilization method. Lamps using the basic stabilization method must be stabilized in accordance with Section 4.4.2 of ANSI C82.6–2015 (R2020). Stabilization is reached when the lamp's electrical characteristics vary by no more than 3 percent in three consecutive 10- to 15-minute intervals measured after the minimum burning time of 30 minutes.

(C) Alternative stabilization method. In cases where switching from the reference ballast to test ballast without extinguishing the lamp is impossible, such as for low-frequency electronic ballasts, the alternative stabilization method must be used. Lamps using the alternative stabilization method must be stabilized in accordance with Section 4.4.3 of ANSI C82.6–2015 (R2020).

(ii) Test measurements.

(A) The ballast input power during operating conditions must be measured in accordance with the methods specified in Sections 6.1 and 6.8 of ANSI C82.6–2015 (R2020).

(B) The ballast output (lamp) power during operating conditions must be measured in accordance with the methods specified in Sections 6.2 and 6.10 of ANSI C82.6–2015 (R2020).

(C) For ballasts with a frequency of 60 Hz, the ballast input and output power shall be measured after lamps have been stabilized according to Section 4.4 of ANSI C82.6–2015 (R2020) using a wattmeter with accuracy specified in Section 4.5 of ANSI C82.6–2015 (R2020); and

(D) For ballasts with a frequency greater than 60 Hz, the ballast input and output power shall have a basic accuracy of ±0.5 percent at the higher of either 3 times the output operating frequency of the ballast or 2.4 kHz.

(iii) Calculations.

(A) To determine the percent efficiency of the ballast under test, divide the measured ballast output (lamp) power, as measured in paragraph (b)(3)(ii) of this section, by the measured ballast input power, as measured in paragraph (b)(3)(ii) of this section. Calculate percent efficiency to three significant figures.

(B) [Reserved]

(c) Standby mode procedure

(1) General instructions.

Measure standby mode energy consumption only for a ballast that is capable of operating in standby mode. Specifications in referenced standards that are recommended, that “shall” or “should” be met, or that are not otherwise explicitly optional, are mandatory. When there is a conflict, the language of the test procedure in this section takes precedence over IEC 63103.

(2) Test conditions and setup.

(i) Establish and maintain test conditions and setup in accordance with paragraph (b)(2) of this section.

(ii) Connect each ballast to a lamp as specified in paragraph (b)(2)(vi) of this section. Note: ballast operation with a reference lamp is not required.

(3) Test method and measurement.

(i) Turn on all of the lamps at full light output. If any lamp is not functional, replace the lamp and repeat the test procedure. If the ballast will not operate any lamps, replace the unit under test.

(ii) Send a signal to the ballast instructing it to have zero light output using the appropriate ballast communication protocol or system for the ballast being tested.

(iii) Stabilize the ballast prior to measurement using one of the methods as specified in Section 5.4 of IEC 63103.

(iv) Measure the standby mode energy consumption in watts using one of the methods as specified in Section 5.4 of IEC 63103.

BACL lighting Inspection and Certification Services:

BACL is the Energy Star testing laboratory, certification body, and verification testing laboratory accredited by the EPA. At the same time we obtain the authorization and recognition of NVLAP (Lab Code: 200707-0), IAS (Accreditation No.: PCA-139, TL-1044, AA-797), CNAS (Registration No.: L2408, L5662, L6290, L9963, L11432, IB0343), A2LA(Certificate No.: 3297.01, 3297.02, 3297.03), and so on. Respectively have testing sites in US, Shenzhen, Dongguan and Kunshan, such places. With the ability to complete the energy efficiency aging detection of 60,000 lights at the same time. BACL is currently a large-scale energy efficiency testing laboratory in China.

We can provide you with testing and certification service, such as US Energy Star, DLC, DOE, CEC Title20, CEC Title24, LDL, FTC Label, European Union ErP, Canada NRCan, UK EST, Australia GEMS/VEET/IPART, Energy Efficiency Label ELI, Hong Kong Energy Efficiency Label and etc.

CN/中国

CN/中国  US/USA

US/USA  KR/Korea

KR/Korea  DE/Germany

DE/Germany  ES/Spain

ES/Spain VN/Việtnam

VN/Việtnam